Capabilities

Quality

UNI EN ISO 9001:2015 UNI EN9100:2018

Production of composite material parts designed for application in aerospace, telecommunications and transport vehicles industries

Design and production of tools

NADCAP NDI

NADCAP COMPOSITES

AAC7118 Rev. G - Nadcap Audit Criteria for Composites

CP

PAR – Prepreg/Adhesive Bonding

Material Class

Class A: Composites

Class B: Adhesive/Adhesive Primer Class D: Core

NC Ply Cutting

Complex Core Processing (Septum, Stabilization or Forming)

Structural Adhesive Bonding

Autoclave

NC Machining/Trimming/Drilling

Miscellaneous Bonding

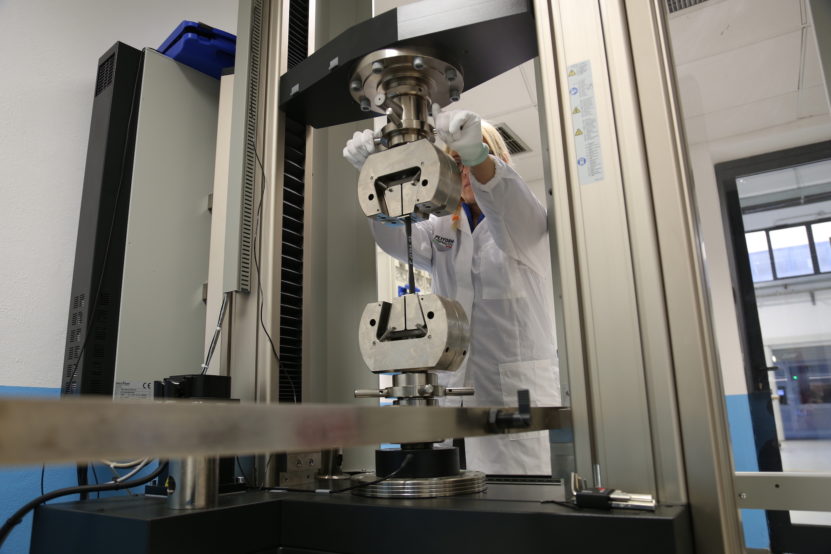

Process Control Testing

Process Capability – CP: Core Processing

Process Capability – PAR: Prepreg/Adhesive Bonding